We generate and develop business opportunities for the food value chain actors. Our R&D is dedicated to addressing the needs of the food industry to achieve sustainable growth through products, technology and tools to fulfil their needs.

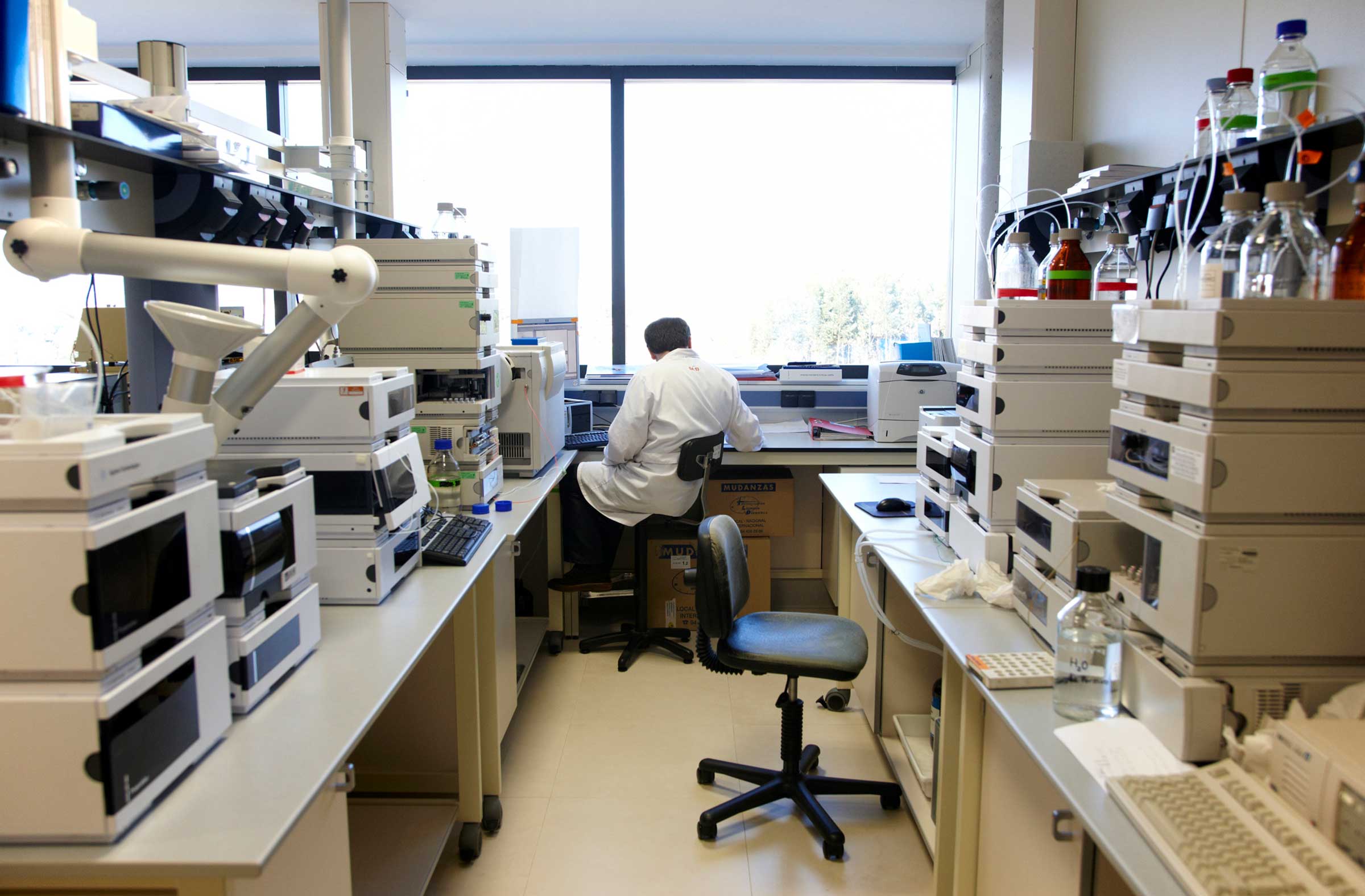

Adding value to the product and increasing the efficiency of products and processes, which are key for the competitiveness of companies

We develop and generate solutions, products, technologies, tools and strategies to ensure short term competitiveness and the long term economic, environmental and social sustainability throughout the food chain. All of this is aimed at:

- Efficient use of resources.

- Increased production efficiency and cost savings.

- Reduction at source of declines, rejects, food losses, food wastage, by-products, waste and discharges.

- Assessment and reduction of the environmental and social impact of food products, processes and facilities throughout the entire life cycle.

- Integration in the circular economy, making optimum use of underused resources.

- Differentiation of products compared with the competitors due to their better environmental and social characteristics.

To reach these objectives, we are working on 5 lines:

Índice de contenidos

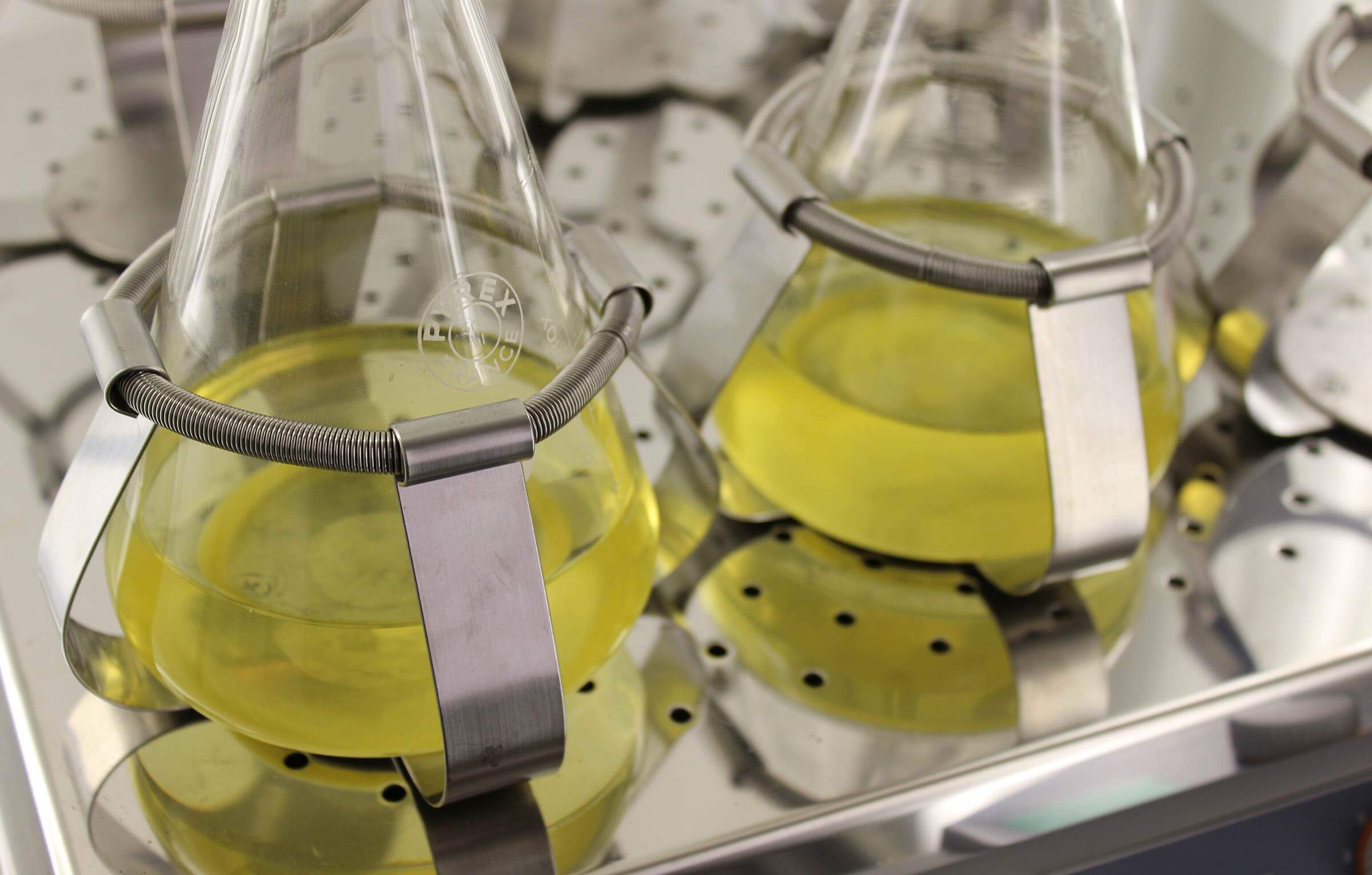

Economic valuation of food by-products: Biorefinery and New bio-based products

We obtain commercial value compounds from food by-products for use in food, for their use as bioenergy or biomaterial.

We offer developments, strategies and processes to obtain commercial value compounds or increased economic-environmental value of products, compounds, substances or molecules based on underused food fractions (surplus, losses and waste, discards, by-products and co-products) for their use as an ingredient, additive, raw material or intermediate material in food for humans, animal feed, bio-energies or bio-materials.

Sustainability assessment and communication

We develop solutions and strategies for the integral socio-economic and environmental improvement of food products throughout their life cycle.

We are working to add value to food through sustainability, developing solutions, strategies and IT tools for the comprehensive economic and socio-environmental improvement of food products throughout their life cycle.

Eco-efficient savings and production

Sustainability and the circular economy is the path for the survival of companies in the long term

We develop and implement solutions to increase the eco-efficiency of companies and their production processes. Comprehensive improvement plans, innovative technological solutions, low-cost operations.

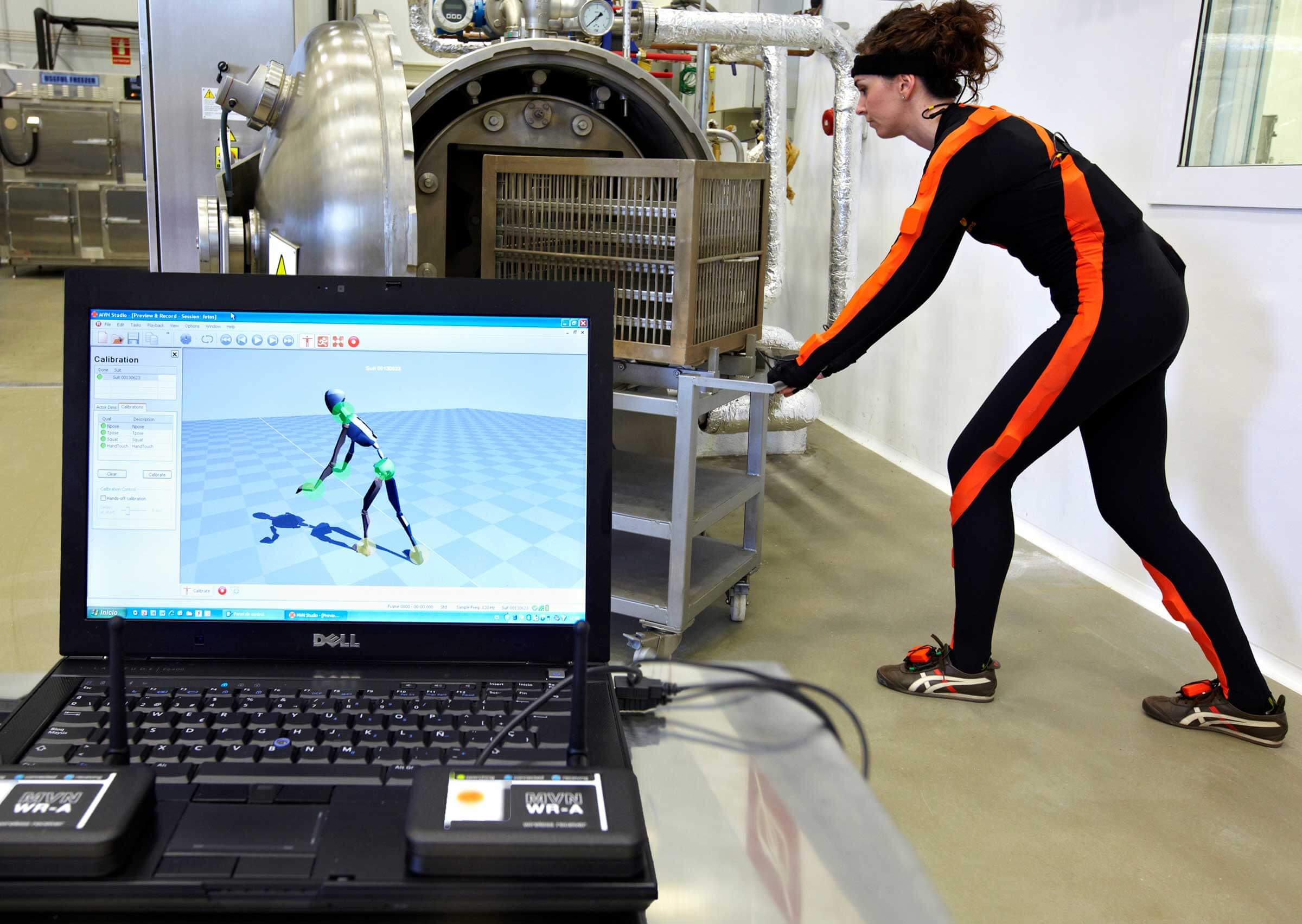

Improved ergonomics of processes

We include the social variable in the improvement of processes, achieving an increase in productivity and competitiveness of the company.

We are working on the social sustainability of food activities through the development of work environments adapted to the specific needs and characteristics of the working population in each company.

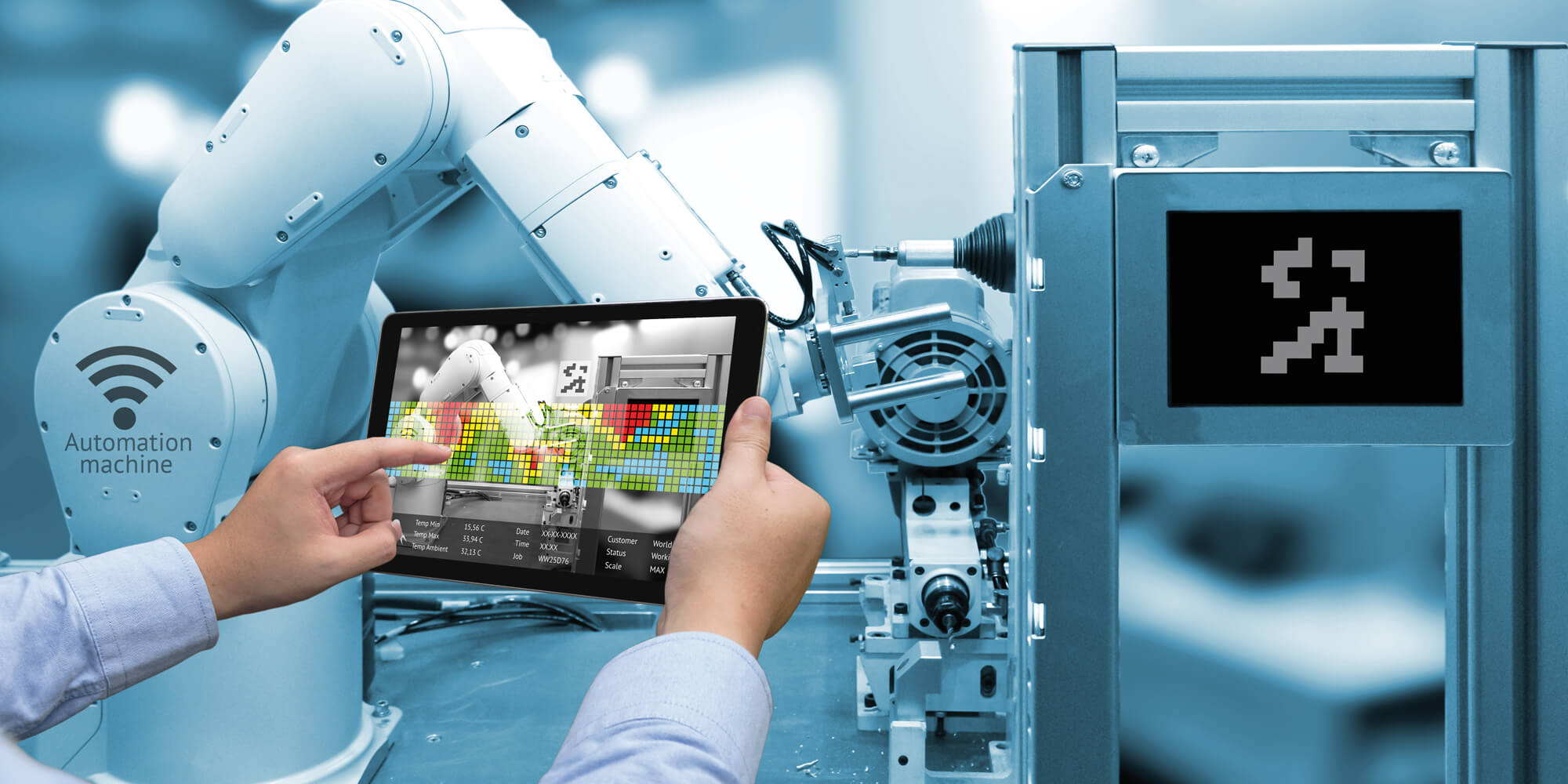

Food Chain 4.0

A world of opportunities to improve the efficiency, safety, quality, traceability, and sustainability of the 4.0 food chain

We develop technological solutions and act to promote the implementation of the 4.0 concept in the food chain.

Specifically, we work in three areas of expertise:

- Advanced sensor systems;

- Predictive quality and processing models;

- Diagnosis 4.0