Food Chain 4.0

A world of opportunities to improve the efficiency, safety, quality, traceability, and sustainability of the 4.0 food chain

We develop technological solutions and act to promote the implementation of the 4.0 concept in the food chain. Specifically, we work in three areas of expertise:

Índice de contenidos

Advanced sensor systems

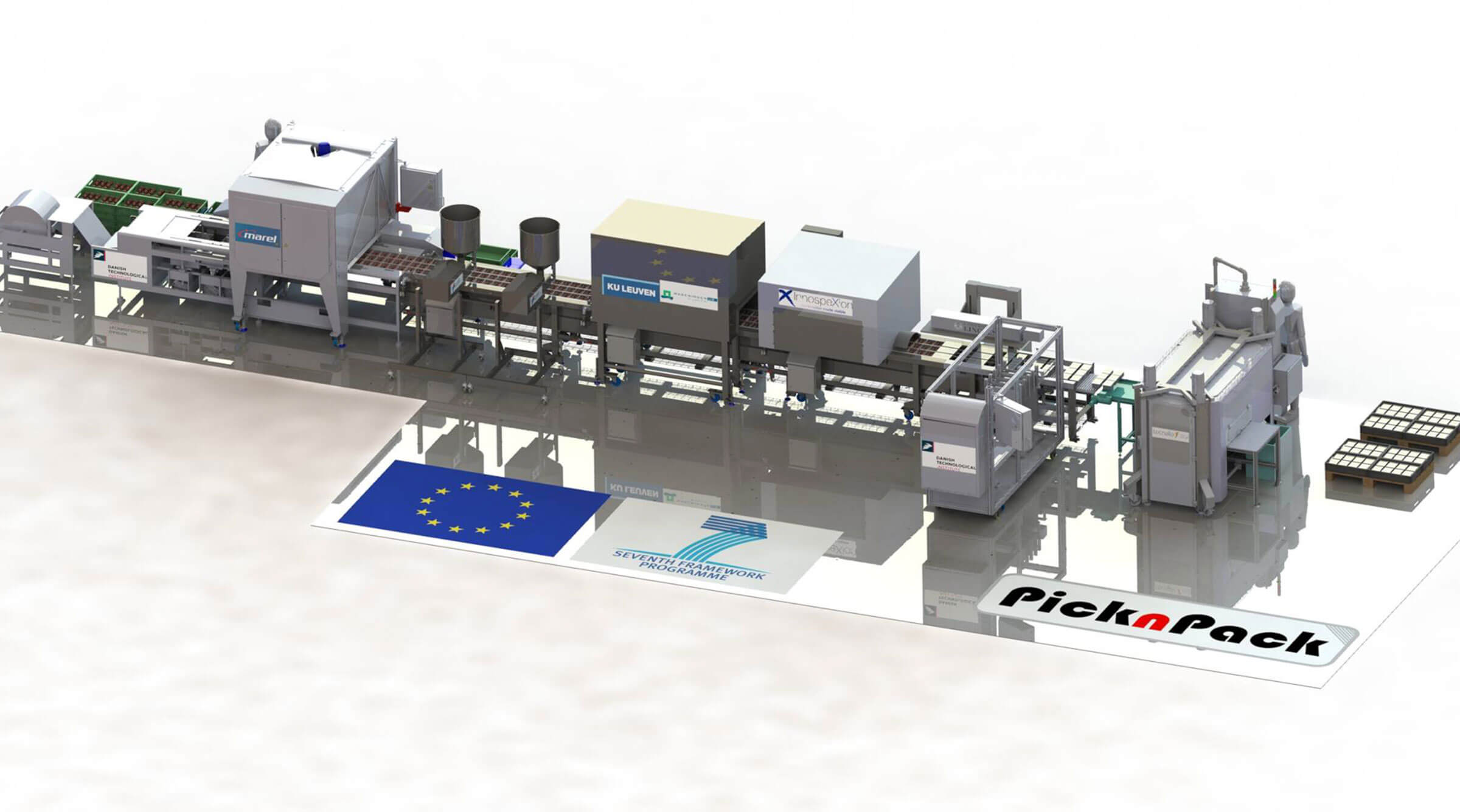

The development of intelligent, non-destructive tools to ensure the quality of food products and processes, thereby allowing increased efficiency of the food value chain and consumer confidence. In this regard, we are specialists in the identification of the critical parameters and attributes concerning quality, efficiency or differentiators in food products and processes.

Predictive quality and processing models

We are specialists in the development of models capable of predicting the quality of products and the efficiency of processes, through complex data processing. We also work on the development and maintenance of ad-hoc calibrations in non-destructive sensors.

Diagnosis 4.0

We prepare personalized diagnoses for food industries to identify their state of maturity regarding the implementation of 4.0 and we design ad-hoc roadmaps for its implementation, collaborating closely with the company throughout the process.

The development of new digital technologies, the internet and new connectivity options open a world of opportunities to improve the efficiency, safety, quality, traceability, and sustainability of the food chain.

The concept of Industry 4.0 is based on the capture and use of information automatically and intelligently, thanks to new digital technologies. This transformation entails obtaining fast information that enables the anticipation of unforeseen events and thus, exponentially enhance business management.

AZTI has been working for years to favor the gradual and comprehensive implementation of 4.0 transformation adapted to the needs of each company and adjusted to its objectives, its reality, and its value chain.

Primary areas of expertise

- Advanced sensing systems: involving the development of intelligent solutions to ensure the quality of food products and processes, which allows increasing the efficiency of the value chain and confidence when it comes to consuming it. Through the rapid and non-destructive identification and measurement of critical quality and process parameters, it is possible to increase efficiency and integrate differentiating elements that add value to your food products and processes.

- Development of predictive and prescriptive models of product and process quality: Data Science applied to quality prediction that enables the fine-tuning of production based on different parameters and anticipating unforeseen events.

- Personalized 4.0 diagnoses 4.0: This involves comprehensive diagnosis geared at food industries from the knowledge of their processes, in order to assess the degree of implementation of different 4.0 technologies, as well as the needs and barriers they may encounter in this area. Preparation of roadmaps to help them on their path towards the 4.0 transformation in a gradual way and adapted to their needs, objectives, and value chain.

- Development of computer tools for economic-environmental evaluation and eco-design of specific products and processes for a sector or company that facilitate the establishment of cost-saving measures and add value to the activity from an environmental and economic perspective. Web-based tools and desktop environment linked to the ERP system. Product examples:

- ECO Tool – Software geared at productive and environmental improvements for food industries: here we have the first ‘user- friendly’ tool for industrial use, which facilitates the identification of the main consumption points, associated costs, and environmental impact of the food industries; furthermore it offers the simulation of new production scenarios.

- LOGISTIKA Software – A GIS application for optimizing the collection, transport, and delivery of freshly obtained unpasteurized milk: This GIS (Geographic Information System) can be personalized; thanks to its intuitive interface it is user friendly.

- Integration of traceability and quality control in advanced systems such as Blockchain technology: aimed at satisfying a growing need for transparency among consumers, as well as to improve production and management among operators of the chain.

- Development of rapid systems or detection solutions (known as “kits”) for quality and food safety parameters adaptable and/or connectable to existing 4.0 solutions. Development of systems for the recognition and prediction of the presence of molecules for the rapid control of raw materials, intermediate and finished products, labeling and compliance with regulated parameters, etc.

- Solutions and services to understand and interact with consumers, through platforms, apps, range options, sensory systems to identify emotions, development of precision nutrition solutions, data analysis and processing, etc.