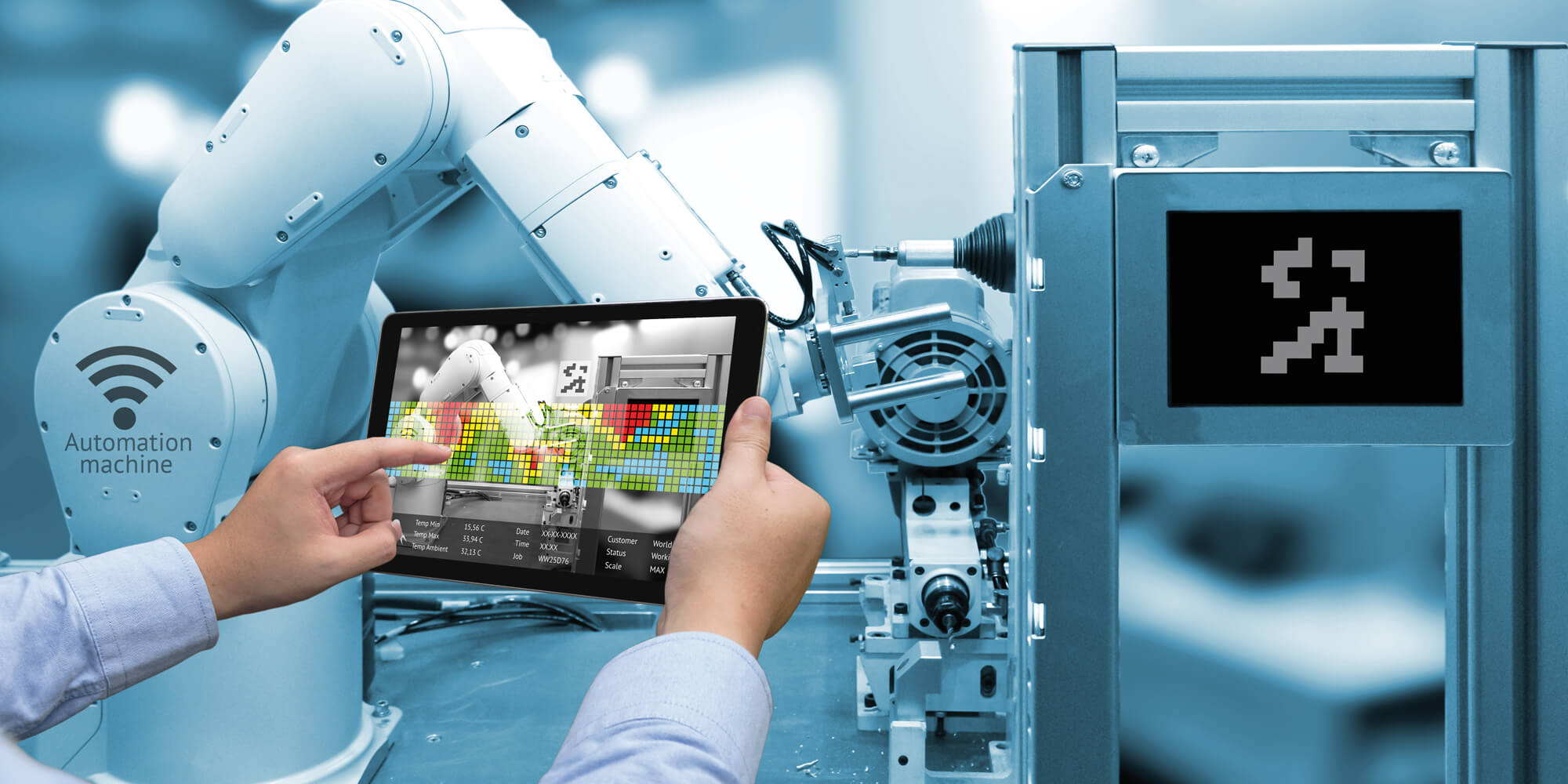

Advanced Sensors

Development of intelligent solutions to ensure the quality of food products and processes.

Through rapid, non-destructive identification and measurement of critical quality and process parameters, it is possible to increase efficiency and integrate differentiators that add value to your food products and processes.

Through advanced sensor technology it is possible:

- Inspect 100% of production.

- Standardise product quality.

- Reduce product wastage and losses.

- Improve traceability.

- Anticipate unforeseen events.

Furthermore, at AZTI we are experts in the development and maintenance of ad-hoc sensor calibrations: (UV/VIS/NIR, RF, MW, etc.) for food applications in the following sectors:

- Food processing: quality of doughs, texture, …

- Fishing sector: freshness of fish, content, type and degree of fat oxidation, identification of fresh/thawed product, shelf life, …

- Fruits and vegetables: degree of maturity of the product, soluble solids content, dry matter, shelf life, …..

- Meat sector: fat content, degree of oxidation, …

- Ingredients: moisture, presence of toxins, …

- Beverage sector: product/water mixture control, pusher optimisation, shrinkage management, …