Beer by-products as an alternative protein source for nutraceuticals and aquaculture feeds

Últimas noticias

Savour and sustainability: insects in gastronomy

Catching fish living at depths of more than 200 meters may have climatic consequences

The future of marine resources and its impact on food security

An innovative solution that is revolutionising the brewing, food and aquaculture industry.

David San Martín, Bruno Iñarra, Jone Ibarruri, Mónica Gutierrez, Ricard Fenollosa, Alicia Estevez, Jose Miguel Martínez, Anna-Maria De Smet and Jaime Zufía

Beer production in Europe has surpassed 400 thousand hectolitres, consolidating it as a strategic economic sector. However, this production process generates large quantities of organic by-products that require efficient management in order not to compromise the productivity and sustainability of the industry.

Índice de contenidos

Beer by-products

Among the most prominent by-products are bagasse and spent yeast, accounting for 80% and 10% respectively of the by-products generated. The production ratios of each by-product per 100 litres of beer are approximately 17 kg of beer bagasse and 3 kg of brewer’s yeast, which implies the generation of large quantities of by-products that, if properly managed, can be used as raw materials for new production processes (Beer statistics, 2020). These by-products are rich in proteins, carbohydrates, fatty acids, vitamins and minerals, making them a valuable source of nutrients. In turn, they contain active biomolecules such as polyphenols, antioxidants, β-glucans (inner layer of the cell wall) or hand proteins (outer layer of the cell wall) that confer different health properties that are in high demand by both the food industry and the feed production sector. However, its high water content limits its shelf life to only 48 hours, which hinders its efficient reuse.

The Life Brewery solution

The Life Brewery project (LIFE16ENV/ES/000160) has emerged as an innovative and sustainable technological solution to make the most of beer by-products. It’s objective is to demonstrate the feasibility of the valorisation of brewery by-products as secondary ingredients for human food and aquaculture.

The proposed solution is based on an enzymatic hydrolysis process that, on the one hand, solubilises compounds of high value for the human food industry in the liquid fraction, while at the same time obtaining a more digestible ingredient for aquaculture feed in the semi-solid fraction. Subsequently, a highly efficient stabilisation process is carried out for both fractions to ensure the nutritional quality and food safety of the ingredients obtained. This approach ensures maximum utilisation of beer by-products for both human and aquaculture food, minimising waste and improving environmental efficiency.

The technological solution developed by the Life Brewery project is safe, flexible and sustainable. It has been demonstrated on a semi-industrial scale and the ingredients obtained have been validated in their final applications. Moreover, this approach is replicable in any region of Europe and adaptable to different scenarios. The solution is based on circular economy, using eco-designed technologies and minimising energy consumption.

Results on the valorisation of beer by-products

As a result of this project, six new ingredients have been developed for application in nutraceuticals and as alternative raw materials for aquaculture feeds. These ingredients provide a sustainable source of protein for nutraceuticals and reduce the dependency on fishmeal in aquaculture, contributing to the sustainability of the sector in the European Union.

In addition to the environmental and competitiveness benefits for the brewing and aquaculture industry, the implementation of this solution leads to an increased awareness of society towards environmental protection and efficient use of resources.

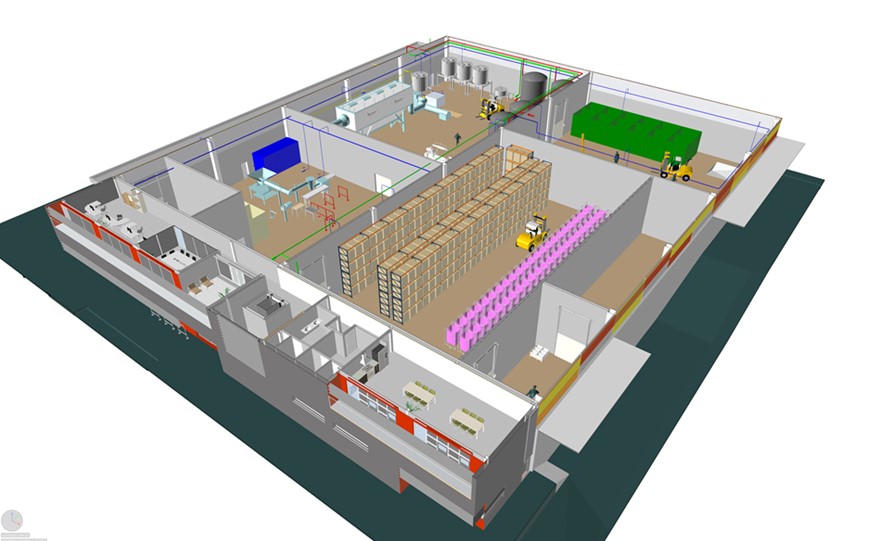

To guarantee the sustainability and efficiency of the production of the ingredients, a production plant has been designed according to ISO 14006 standards. This plant incorporates environmental aspects that make the production of these ingredients more sustainable and efficient. Site analysis for the selection of a thermal envelope to reduce heat losses/excess gains;

- bioclimatic design to ensure solar gains and protection to reduce energy demand; a range of environmental certification criteria such as BREEAM, LEED and WELL;

- selection of materials/structures based on life cycle analysis, Cradle to grave, EPDs, etc.;

- responsible sourcing based on ISO 14006 standards. ;

- responsible sourcing based on ISO 14001;

- EU legislation, taking into account Energy Performance Building Directives (EPBD, NZEB), National Energy Efficiency and Energy and Climate Action Plans (NEEAP and NECP) and/or

- energy performance simulations including different renewable energy analyses are several of the aspects included in the plant design.

This consortium has the capacity to offer a customised solution, the development of detailed engineering and even a turnkey solution.

The two potential markets for the ingredients produced are:

- Food and nutraceuticals based on their high quality protein content and composition rich in functional biomolecules.

- Aquaculture on the basis of its high nutritional value, capable of meeting the high demand for new raw materials.

AZTI (Marine and Food Research Centre) has led the initiative in collaboration with the main actors in the value chain: IRTA (Catalan Institute of Agri-Food Research and Technology), Riera Nadeu (a Catalan company specialising in dehydration solutions) and LKS Krean (a Basque company specialising in engineering processes for waste recovery facilities.), and, finally, ‘The Brewers of Europe’ (association of european brewers).

The launch of a newcircular economy-based activity for the valorisation of beer by-products will contribute to the improvement of the competitiveness and sustainability of the brewing sector, as well as the food industry and the aquaculture sector by bringing secondary raw materials to the market for the production of ingredients for nutraceuticals and aquaculture feed.