Content index

Near-Infrared Spectroscopy (NIR) has become, in recent years, a strategic technology for the rapid, non-destructive and efficient analysis of physicochemical properties in foods and raw materials. Its ability to deliver real-time information without damaging the sample has positioned it as a core tool for advancing digitalisation, automated quality control and sustainability in the food sector—at a time when companies are increasingly seeking more sustainable processes and data-driven decision-making.

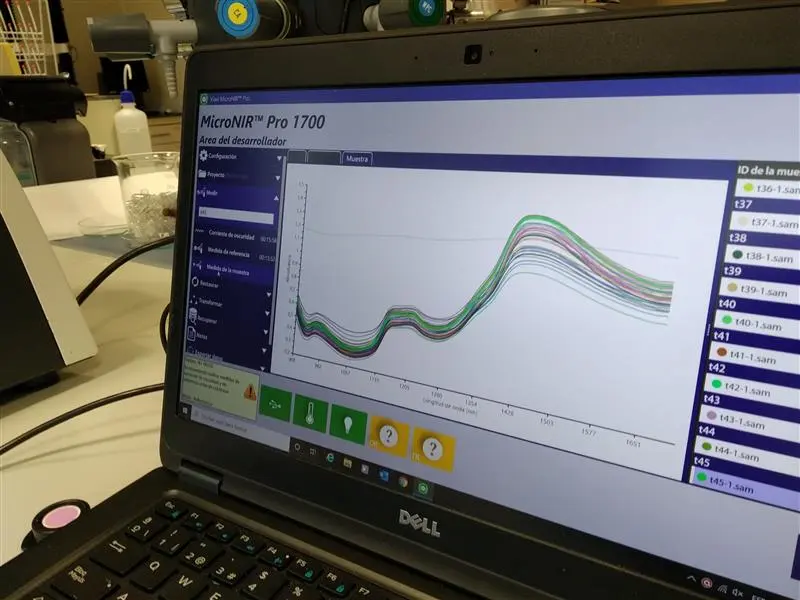

At AZTI, we have been researching, validating and implementing NIR-based applications for many years, with a clear objective: to provide the agri-food industry with digital tools that improve process control, reduce losses and increase the reliability of the final product, helping companies move towards higher standards of food quality and safety.

NIR spectroscopy (Near-Infrared Spectroscopy) is a technique that uses invisible light just beyond the red region of the visible spectrum to analyse what is inside a material or food product—without touching it or causing any damage. When NIR light interacts with a product, specific wavelengths are absorbed by functional groups present in molecules such as water, fats, sugars or proteins. This absorption generates a characteristic spectrum, a kind of unique “fingerprint” for each matrix, reflecting its internal composition.

Although NIR spectra contain a large amount of valuable information, they cannot be interpreted directly. To convert this complex signal into meaningful parameters related to food quality or safety, it is essential to apply chemometrics—the discipline that combines advanced statistics and mathematical modelling (including machine learning techniques) to extract useful information. Thanks to chemometrics, NIR spectroscopy becomes a predictive tool, capable of delivering fast and reliable data for industrial applications.

NIR spectroscopy stands out for being fast, non-destructive, clean and cost-effective. Unlike traditional analytical methods, it does not require reagents, does not generate hazardous waste, and provides real-time results. This sustainable and efficient nature has driven its adoption and integration into production lines where large numbers of batches are processed daily or where continuous quality monitoring is required.

These advantages translate into direct benefits for the food industry:

Speed: analyses completed in seconds.

Continuous monitoring of quality parameters during production without interrupting processes.

Non-destructive analysis: since products are not destroyed, it becomes possible to monitor up to 100% of production.

Significant cost reduction in analytical testing by avoiding consumables and lengthy laboratory procedures.

Inline application: enables process monitoring without stopping production.

Improved food safety, helping to detect deviations or adulterations before products reach the market.

Overall, NIR spectroscopy is a key technology for building a more digital, efficient and sustainable food industry, capable of making real-time, data-driven decisions.

Interpreting NIR spectra is one of the main challenges of this technique, as the signal contains complex, overlapping and multidimensional information. Unlike analytical techniques where each peak is directly associated with a specific compound, NIR spectra reflect the superposition of multiple molecular vibrations and overtones, preventing direct interpretation and requiring advanced mathematical processing to extract useful chemical information.

For this reason, chemometrics lies at the heart of the technology, providing the statistical methods and algorithms needed to transform raw spectra into useful, reliable and directly applicable information for the food industry.

Its key functions include:

Spectral pre-processing

Chemometrics first addresses signal pre-processing, applying corrections to reduce noise, scattering and instrumental variability. Techniques such as derivatives, scatter correction or smoothing result in cleaner, more comparable spectra, which are essential for any subsequent analysis.

Pattern recognition

Using techniques such as Principal Component Analysis (PCA), it is possible to identify similarities between samples, detect anomalies and visualise trends that would otherwise go unnoticed. This type of analysis helps to classify products, identify adulteration or detect batches with abnormal behaviour.

Quantitative and qualitative prediction models

The next step involves building quantitative and qualitative models. Algorithms such as PLSR (Partial Least Squares Regression), PLS-DA (Partial Least Squares Discriminant Analysis) and other machine learning approaches link spectral information to physicochemical parameters obtained through reference methods (moisture, fat, salt content, ripeness, etc.). As a result, spectra are transformed from simple “curves” into real-time predictions, eliminating the need for routine laboratory analyses.

Management of large data volumes

Chemometrics also supports the management and interpretation of large datasets. A single NIR spectrum may be correlated with hundreds of variables per sample, requiring statistical tools capable of handling this complexity, structuring the data and generating robust, reliable models.

Together, the integrated use of NIR spectroscopy and chemometrics enables the food industry to move towards more efficient, reproducible and data-driven processes, reducing uncertainty and improving continuous, sustainable quality control.

Through various research projects and in close collaboration with industry, AZTI has developed multiple applications of this technology for quality and safety control in the food industry, including:

Acrylamide detection

Monitoring of effluents in dairy processing plants

Discrimination between fresh products and previously frozen foods

Detection of products injected with water and additives

Monitoring of sauce production processes

Control of salt content in foods

Assessment of fruit ripeness

Compositional analysis of foods (fat, protein, moisture, ash, etc.)

Quality control of by-products

The combination of NIR spectroscopy and chemometrics represents a powerful pathway towards Food Industry 4.0, where data enables faster, more accurate and more sustainable decision-making. At AZTI, we continue to develop advanced sensing solutions to help companies improve food quality and safety across all stages of production.